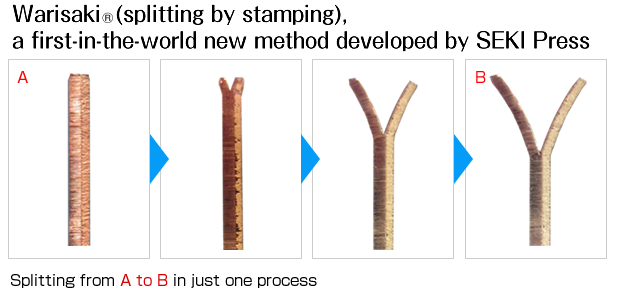

New Warisaki®technology

New Warisaki®technology

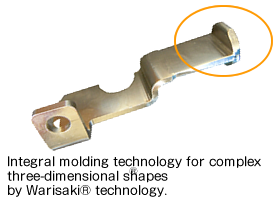

With this innovative technique, metal can be split by a press die into two parts and then complex three-dimensional shapes can be produced by metal press fabrication, something never before possible.

We have currently succeeded in dividing 0.6 mm steel plates

Warisaki®fabrication is possible with five types of material: iron, copper, brass, aluminum, and stainless steel

[Video] Warisaki® method

Benefits of the Warisaki® method

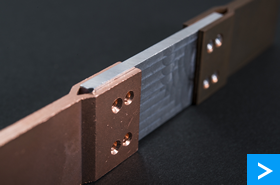

Complex three-dimensional shapes conventionally only achievable by methods such as cutting, forging, and die casting can be manufactured by integrated fabrication using progressive metal fabrication.

Manufacturing can be done integrally, so there are no joints and strength is greater. On top of that, redundant materials are not needed, so costs can be reduced.

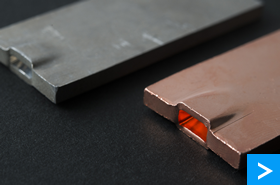

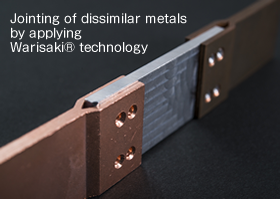

Jointing by inserting the material to connect into the divided part gives a contact surface area double that of conventional methods, increasing the strength of the product.

Four Warisaki®methods

More information on the Warisaki®method